Box anchors stand as a testament to maritime innovation, combining simplicity with exceptional functionality. These ingenious devices secure vessels to the seabed, providing stability in various nautical conditions. But what exactly sets box anchors apart from their counterparts?

At its core, a box anchor consists of a weighted, box-shaped structure designed to dig into the seafloor. This unique shape allows it to penetrate various types of sea bottoms, from soft mud to harder, more resistant surfaces. The box anchor’s journey began in the mid-20th century, evolving from traditional anchor designs to meet the growing demands of modern boating and shipping industries.

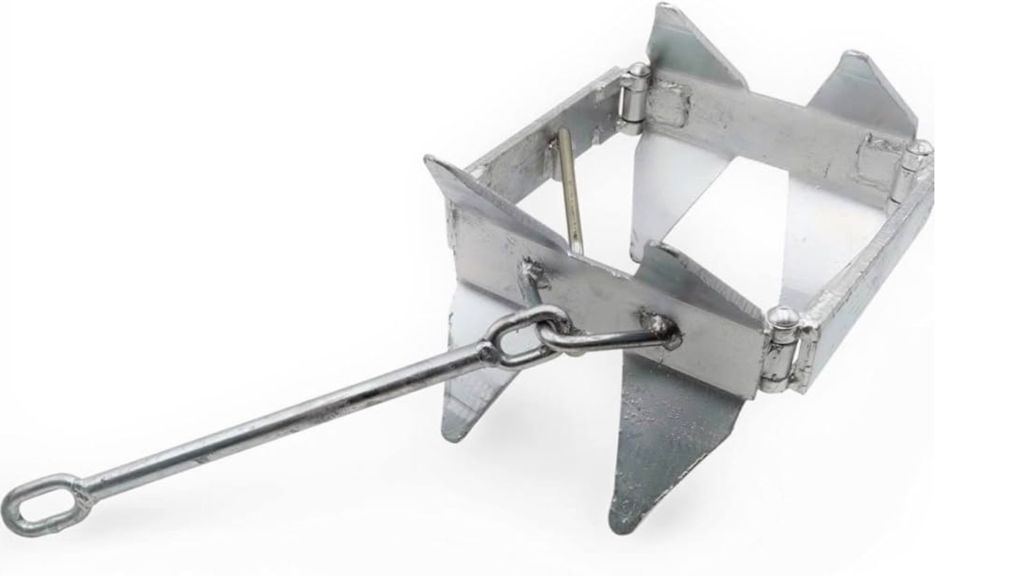

Anatomy of a Box Anchor

Key Components

The brilliance of a box anchor lies in its straightforward yet effective design. Picture a sturdy, hollow box with an open bottom and top. Constructed from long-lasting materials such as galvanized steel or stainless steel, this structure constitutes the bulk of the anchor.

At the top, you’ll find a robust shackle or ring, serving as the connection point for the anchor rode. The bottom edge often features sharp, reinforced corners that aid in penetrating the seabed. Some models incorporate flukes or fins along the sides, enhancing the anchor’s ability to dig in and maintain its position.

Materials Used

Manufacturers craft box anchors from high-grade materials designed to withstand the harsh marine environment. Galvanized steel remains a popular choice, offering excellent corrosion resistance and durability. For boaters seeking premium options, stainless steel variants provide superior longevity and a polished aesthetic.

Some modern designs incorporate lightweight alloys or composite materials, striking a balance between strength and portability. These innovative materials cater to smaller vessels or situations where weight considerations prove crucial.

How Box Anchors Work

Principle of Operation

The effectiveness of a box anchor stems from its ability to leverage the forces acting upon it. When deployed, the anchor’s weight causes it to sink and make initial contact with the seabed. As the vessel drifts or experiences wind and current forces, it pulls on the anchor rode.

This pulling action causes the box anchor to tilt and begin digging into the bottom. The sharp edges and open design allow it to penetrate the seabed material easily. As it burrows deeper, the surrounding substrate presses against the anchor’s surfaces, creating substantial resistance.

Holding Power Mechanism

The true magic of a box anchor reveals itself once it’s fully set. The large surface area of the box sides creates significant friction with the seabed material. This friction, combined with the weight of the substrate filling the anchor’s hollow interior, generates impressive holding power.

As forces increase, the anchor tends to dig deeper, further enhancing its grip. This self-burying characteristic enables box anchors to maintain their position even in challenging conditions, providing boaters with peace of mind during extended stays or in rough weather.

Types of Box Anchors

Traditional Box Anchors

The classic box anchor design features a simple, rectangular shape with open ends. These anchors rely primarily on their weight and the friction created by their large surface area to maintain position. Traditional box anchors excel in softer bottoms like mud or sand, where they can easily penetrate and set.

Modern Variations

Innovation drives the evolution of box anchor design. Modern variations often incorporate additional features to enhance performance:

- Hinged Box Anchors: These models feature a collapsible design for easier storage, addressing one of the main drawbacks of traditional box anchors.

- Finned Box Anchors: By adding fins or flukes to the sides, these anchors increase their ability to dig in and resist lateral movement.

- Hybrid Designs: Some manufacturers combine box anchor principles with other anchor types, creating unique hybrids that offer the best of both worlds.

- Weighted Box Anchors: These incorporate additional weight, often in the form of lead inserts, to increase holding power without significantly increasing size.

Advantages of Box Anchors

Superior Holding Power

Box anchors boast exceptional holding power relative to their size and weight. Their design allows them to dig deep into the seabed, creating a strong anchor point that resists pulling forces from multiple directions. This superior holding ability proves particularly valuable in areas with strong currents or changeable wind conditions.

Versatility in Various Sea Beds

Unlike some anchor types that perform well only in specific bottom conditions, box anchors adapt to a wide range of seabed materials. From soft mud to rocky bottoms, these anchors demonstrate remarkable versatility. This adaptability eliminates the need for boaters to carry multiple anchor types, streamlining their onboard equipment.

Selecting the Right Box Anchor

Size Considerations

Choosing the appropriate box anchor size depends on several factors:

- Vessel Length: Longer boats generally require larger anchors to provide adequate holding power.

- Vessel Weight: Heavier vessels exert more force on the anchor, necessitating a larger size.

- Expected Conditions: Areas prone to strong winds or currents may call for a larger anchor than typically recommended.

- Bottom Type: Softer bottoms may require a larger anchor to achieve the same holding power as in firmer substrates.

Weight-to-Boat Ratio

As a general rule, box anchors should weigh approximately 1 pound for every 2 feet of boat length. However, this ratio serves merely as a starting point. Factors such as boat design, typical usage scenarios, and personal preferences influence the ideal anchor weight.

For example, a 30-foot sailboat might use a 15-pound box anchor in moderate conditions. However, for extended stays or challenging environments, opting for a 20-pound or even 25-pound anchor could provide added security.

Proper Deployment Techniques

Step-by-Step Guide

- Approach: Position your vessel into the wind or current, whichever is stronger.

- Slow Down: Reduce speed as you near your intended anchoring spot.

- Prepare: Lower the anchor to water level, ensuring the rode is clear of obstructions.

- Deploy: Gently lower the anchor to the bottom, allowing it to touch down vertically.

- Set: Slowly reverse the vessel, paying out rode as you go. Aim for a scope of at least 7:1 (rode length to water depth).

- Secure: Once you’ve paid out sufficient rode, cleat it off and allow the anchor to set.

- Check: Observe nearby landmarks or use GPS to ensure your vessel isn’t dragging.

Common Mistakes to Avoid

- Insufficient Scope: Failing to pay out enough rode reduces the anchor’s effectiveness.

- Rapid Deployment: Dropping the anchor quickly may cause it to land on its side, preventing proper setting.

- Ignoring Conditions: Failing to account for wind shifts or tidal changes can lead to dragging.

- Overlooking Bottom Type: Not adjusting your technique based on the seabed composition can result in poor holding.

Maintenance and Care

Cleaning Procedures

- Rinse Thoroughly: Rinse the anchor well with clean water after each use to eliminate any trace of salt, sand, or debris.

- Inspect: Check for any signs of wear, corrosion, or damage, particularly around the shackle and corners.

- Brush Clean: Use a stiff brush to remove stubborn marine growth or accumulated grime.

- Dry Completely: Allow the anchor to dry fully before storage to prevent rust formation.

Storage Recommendations

- Clean Environment: Store the anchor in a dry, well-ventilated area to prevent moisture accumulation.

- Protective Covering: Consider using a canvas or plastic cover to shield the anchor from dust and scratches.

- Proper Positioning: Keep the anchor upright while storing it to keep it from deforming.

- Regular Checks: Periodically inspect stored anchors for any signs of corrosion or damage.

Box Anchors vs. Other Anchor Types

Comparative Analysis

Box anchors offer unique advantages over traditional anchor designs:

- Holding Power: Box anchors generally provide superior holding power relative to their weight compared to fluke or plow anchors.

- Versatility: Unlike specialized anchors, box anchors perform well in various bottom types.

- Quick Setting: The box design allows for rapid penetration and setting in most conditions.

- Reset Ability: If disturbed, box anchors tend to quickly re-establish their hold without intervention.

Situational Advantages

While box anchors excel in many scenarios, certain situations highlight their strengths:

- Crowded Anchorages: The efficient holding power allows for shorter scope, saving space in busy areas.

- Variable Conditions: In locations with changing winds or currents, box anchors maintain their grip effectively.

- Extended Stays: The reliable holding power of box anchors provides peace of mind for longer anchoring periods.

- Rocky Bottoms: The box design can often find purchase in areas where other anchor types might slip.

Real-World Applications

Recreational Boating

Box anchors have gained popularity among recreational boaters for their ease of use and reliability. From small day-sailors to larger cruising yachts, these anchors provide a versatile solution for various anchoring needs. Weekend warriors appreciate the quick setting characteristics, while long-distance cruisers rely on the dependable holding power for peaceful nights at anchor.

Commercial Shipping

In the commercial sector, box anchors find use in specialized applications. Smaller commercial vessels, such as survey boats or work barges, often employ box anchors for their ability to hold position in challenging conditions. Some larger ships use box anchors as secondary or stern anchors, complementing their primary anchoring systems.

Expert Tips for Optimal Performance

Maximizing Holding Power

- Proper Sizing: Always err on the side of a slightly larger anchor for increased security.

- Adequate Scope: Use a minimum 7:1 scope in normal conditions, increasing to 10:1 or more in rough weather.

- Tandem Anchoring: For extreme conditions, consider deploying two box anchors in a V-configuration for enhanced holding.

- Allow Setting Time: After deployment, give the anchor time to fully set before applying significant loads.

Adapting to Different Weather Conditions

- Wind Shifts: In areas prone to wind shifts, deploy a second anchor or use a longer scope to accommodate swinging.

- Storm Preparation: Before severe weather hits, re-evaluate your anchor’s size and position, potentially moving to a more sheltered location.

- Tidal Considerations: In areas with significant tidal range, ensure sufficient scope to accommodate water level changes.

- Current Interactions: When anchoring in strong currents, position your vessel to minimize strain on the anchor system.

Future Innovations in Box Anchor Design

Emerging Technologies

The world of box anchors continues to evolve, with several exciting developments on the horizon:

- Smart Anchors: Integration of sensors and GPS technology to provide real-time data on anchor position and holding status.

- Biodegradable Materials: Research into environmentally friendly anchor materials that maintain strength while reducing ecological impact.

- Shape-Memory Alloys: Exploration of materials that can change shape under different conditions, potentially enhancing setting and retrieval.

- 3D-Printed Anchors: Customized anchor designs tailored to specific vessels or anchoring conditions.

Potential Improvements

As technology advances, several areas of box anchor design show promise for enhancement:

- Weight Reduction: Development of stronger, lighter materials to improve handling without sacrificing holding power.

- Self-Aligning Mechanisms: Features that ensure the anchor lands in the optimal position for setting, regardless of deployment method.

- Enhanced Corrosion Resistance: New coatings or alloys that provide superior protection against the harsh marine environment.

- Modular Designs: Anchors with interchangeable components, allowing users to adapt to different conditions or vessel requirements.

Box anchors represent a pinnacle of maritime engineering, combining simplicity, versatility, and exceptional performance. Their unique design addresses many of the challenges faced by traditional anchor types, offering boaters a reliable solution for a wide range of anchoring scenarios.

From the casual weekend sailor to the seasoned ocean voyager, box anchors provide the confidence needed to enjoy time at anchor, knowing your vessel remains secure. As technology continues to advance, these already impressive devices stand poised for even further improvement, cementing their place as an essential tool in the modern mariner’s arsenal.

Whether you’re outfitting a new vessel or considering an upgrade to your existing ground tackle, box anchors deserve serious consideration. Their proven track record, combined with ongoing innovations, ensures that box anchors will continue to play a crucial role in maritime safety and convenience for years to come.

Related FAQs

What makes box anchors different from traditional anchors?

Box anchors feature a unique box-shaped design that allows them to dig into various seabed types, providing superior holding power. Unlike traditional anchors, their large surface area and sharp edges ensure rapid penetration and strong resistance to pulling forces, making them highly versatile and reliable in different marine conditions.

How do I choose the right size box anchor for my boat?

Selecting the right size box anchor depends on factors such as your vessel’s length, weight, and the expected anchoring conditions. A general guideline is to choose an anchor weighing approximately 1 pound for every 2 feet of boat length. However, in areas with strong currents or winds, opting for a larger anchor may provide additional security.

What materials are used in the construction of box anchors?

Galvanized steel and stainless steel, two common materials for box anchors, are very long-lasting and resistant to corrosion. Some modern designs incorporate lightweight alloys or composite materials, balancing strength with portability for smaller vessels or weight-sensitive applications.

How should I properly deploy a box anchor?

To deploy a box anchor, position your vessel into the wind or current, lower the anchor gently to the seabed, and pay out enough rode to achieve a scope of at least 7:1. Slowly reverse the vessel to allow the anchor to dig in and set, then secure the rode and monitor your position to ensure the anchor holds.

How can I maintain my box anchor to ensure its longevity?

Make sure to wash the anchor well with fresh water after every usage to get rid of any salt or debris. Before putting it away, give it a thorough inspection for damage or wear, use a sharp brush to remove any marine vegetation, and let it dry entirely. Always inspect the anchor for corrosion and other problems before storing it in a dry, well-ventilated place.