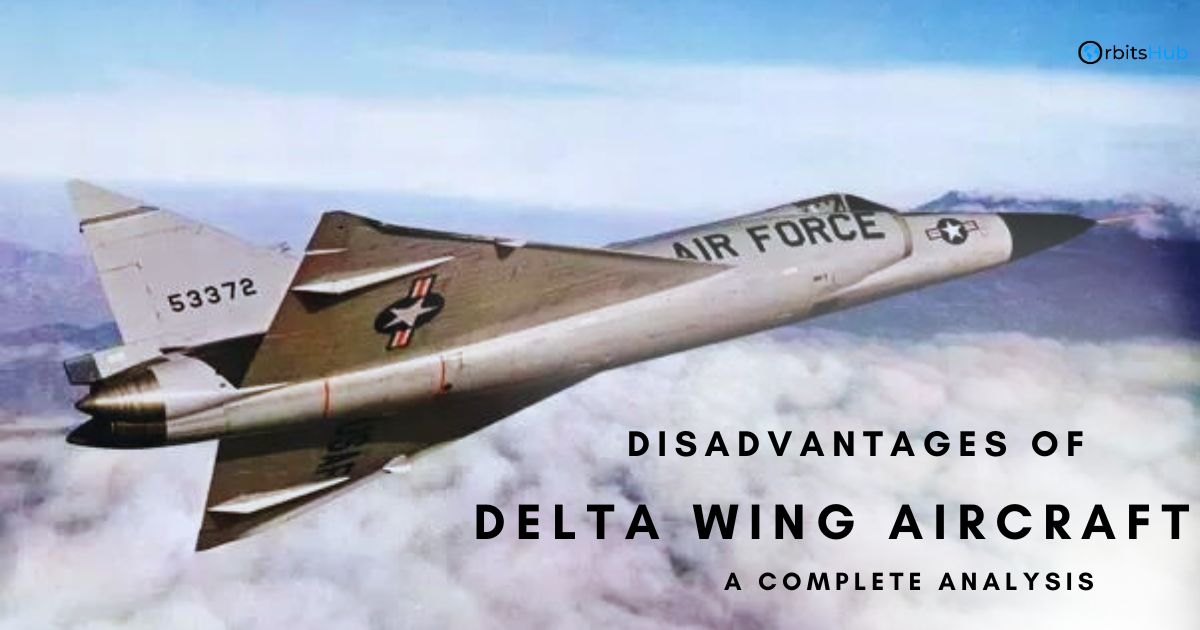

Delta wing aircraft have long been admired for their sleek design and impressive performance characteristics, especially at high speeds. Triangular, swept-back wings distinguish these aircraft, contributing to military and civilian aviation. However, despite their advantages, delta-wing aircraft have disadvantages that can impact their performance, handling, and operational costs.

Aerodynamic Challenges of Delta Wing Aircraft

High Drag at Low Speeds

One of the primary disadvantages of delta-wing aircraft is the increased drag at lower speeds. The broad, swept-back wings that contribute to excellent performance at high speeds become a hindrance during takeoff, landing, and low-speed maneuvers. The large surface area of the wings creates significant drag, requiring more thrust to maintain speed and stability. This increased drag not only affects fuel efficiency but also necessitates more powerful engines, which can add to the overall weight and cost of the aircraft.

Moreover, the high drag at low speeds can lead to longer takeoff and landing distances, which limits the types of airports and runways from which delta-wing aircraft can operate. This limitation is particularly significant for military aircraft that may need to operate from short or rough airstrips. The increased drag also impacts the aircraft’s maneuverability at low speeds, making it less agile and responsive than other wing configurations.

Difficult Stall Recovery

Delta wing aircraft are also known for their challenging stall characteristics. A stall occurs when the aircraft’s wings can no longer generate sufficient lift, usually due to a high angle of attack. In traditional wing designs, stalls can often be recovered by lowering the nose of the aircraft to reduce the angle of attack. However, delta wings behave differently in a stall.

When a delta wing aircraft stalls, the entire wing loses lift simultaneously rather than gradually from the wingtips inward, as in other wing designs. This can lead to a rapid and uncontrollable descent, making stall recovery more complex. Pilots must be highly trained and aware of the specific stall characteristics of delta-wing aircraft to manage this situation effectively. The difficulty in stall recovery is a significant drawback, particularly in high-stress or combat scenarios where quick responses are crucial.

Handling and Control Limitations

Reduced Lift-to-Drag Ratio

Another notable disadvantage of delta-wing aircraft is the reduced lift-to-drag ratio compared to other wing configurations. The lift-to-drag ratio is a critical factor in determining the efficiency of an airplane. A lower ratio means the aircraft generates less lift for a given amount of drag, which can affect performance and fuel efficiency.

With their large surface area and unique shape, Delta wings often generate more drag relative to the lift they produce. This characteristic makes them less efficient in level flight, particularly at lower speeds or higher altitudes. The reduced lift-to-drag ratio also impacts the aircraft’s range, requiring more fuel to cover the same distance as aircraft with more efficient wing designs. This limitation is especially relevant for long-range missions or commercial flights, where fuel efficiency and range are critical considerations.

Poor Low-Speed Maneuverability

Low-speed maneuverability is another area where delta-wing aircraft face significant challenges. The wide, triangular shape of the wings, while beneficial at high speeds, becomes a liability when the aircraft slows down. The large surface area increases drag, and the lack of traditional control surfaces, such as flaps and ailerons, further complicates low-speed handling.

Delta wing aircraft often rely on control systems such as elevons (a combination of elevator and aileron functions) to manage pitch and roll. While these systems work well at high speeds, they become less effective as the aircraft slows down, leading to sluggish response times and reduced maneuverability. This limitation can be particularly problematic during landing approaches or when precise control is needed at low speeds.

Structural and Maintenance Challenges

Increased Structural Stress

The unique shape of delta wings also leads to increased structural stress, particularly at high speeds or during high-G maneuvers. The wide wingspan and lack of traditional support structures, such as wing spars, mean that the wings must bear a significant amount of the aerodynamic load. This stress can lead to faster wear and tear, requiring more frequent maintenance and inspections to ensure the aircraft remains airworthy.

In addition, the increased stress on the wings can lead to issues such as metal fatigue, cracks, or even structural failure if not adequately managed. This risk is especially pronounced in military aircraft, which often undergo extreme maneuvers and operate at the limits of their performance envelopes. The need for regular maintenance and inspections adds to the operational costs of delta-wing aircraft, making them less cost-effective in the long run.

Complex and Costly Maintenance

Maintaining delta-wing aircraft can be more complex and costly than other wing configurations. The unique design of the wings often requires specialized tools and equipment for inspections and repairs. In addition, the lack of traditional control surfaces means that the aircraft’s control systems are more integrated and complex, requiring highly skilled technicians to service them.

The increased maintenance demands can lead to higher operational costs. This is especially true for military operators, who must keep their aircraft in peak condition. The complexity of maintenance procedures increases the length of downtime for repairs and inspections. This reduces the aircraft’s availability for missions or commercial flights. This limitation is a significant disadvantage for operators who require high levels of reliability and availability from their planes.

Operational Limitations: Delta Wing Aircraft

Limited Operational Flexibility

Due to their unique design characteristics, Delta wing aircraft often need more operational flexibility. The increased drag at low speeds, poor low-speed maneuverability, and challenging stall characteristics contribute to a narrower operational envelope. This limitation means delta wing aircraft are often best suited for specific roles, such as high-speed interceptors or supersonic bombers, rather than general-purpose or multirole aircraft.

The limited operational flexibility also affects the types of missions that delta-wing aircraft can perform. For close air support or ground attack missions, they may need to be better suited. These missions require slow, precise maneuvering, and they should be better suited for that. Commercial delta wing aircraft may need help operating from smaller airports. Their operational scope could be further reduced due to limited infrastructure in some regions.

High Operating Costs

Increased maintenance demands, fuel consumption, and limited operational flexibility lead to higher operating costs for delta-wing aircraft. These costs can significantly burden operators, particularly in commercial or military contexts where budgets are often tight. High operational expenses make Delta wing aircraft less competitive than designs with equivalent performance and cheaper costs.

For commercial operators, the higher operating costs can lead to increased ticket prices. This can make Delta wing aircraft less attractive for airlines, as they may experience reduced profitability. In the military context, the higher costs can limit the number of aircraft that can be procured or maintained. This reduction in the number of aircraft can, in turn, decrease overall fleet size and capability. This economic disadvantage is crucial for any operator investing in delta-wing aircraft.

While delta-wing aircraft offer unique advantages, particularly at high speeds, they also have significant disadvantages that can impact their performance, handling, and operational costs. These aircraft have aerodynamic issues, structural stress, and high operating expenses that operators and designers must consider.

Understanding the disadvantages of delta-wing aircraft is essential for making informed decisions about their use and development. For those interested in exploring more about delta wing aircraft or seeking expert guidance on aviation and maritime matters, consider reaching out to Orbitshub, a consultancy services company with expertise in these fields.