Ship trim, the difference between a vessel’s forward and aft drafts, is a crucial factor in maritime performance. It influences fuel efficiency, speed, and navigational characteristics. Proper trim management reduces hull resistance, cutting fuel consumption and emissions, while optimizing speed and maneuverability. Additionally, it enhances stability and safety, particularly in challenging conditions like shallow waters. Modern technologies, including AI and dynamic control systems, are revolutionizing trim optimization, contributing to sustainable maritime operations by balancing efficiency and environmental considerations.

Defining Ship Trim

Ship trim refers to the difference between the forward and aft drafts of a vessel. When a ship floats evenly, with equal drafts at both ends, it’s considered to be at even keel. However, most vessels operate with a slight trim, either by the bow (forward) or by the stern (aft). This subtle inclination significantly influences the vessel’s behavior in water.

The Physics of Ship Trim

The principles of naval architecture dictate that a ship’s trim affects its hydrodynamic properties. As a vessel moves through water, it creates pressure distributions along its hull. These pressure fields vary depending on the trim condition, altering the ship’s resistance profile. Understanding these physical interactions forms the foundation for optimizing vessel performance through trim adjustments.

Trim’s Influence on Vessel Efficiency

Proper trim management stands as a key factor in maximizing a ship’s operational efficiency. Let’s examine how trim impacts two critical aspects of vessel performance: fuel consumption and speed.

Fuel Consumption and Trim

Did you know that even minor adjustments in trim can lead to substantial fuel savings? It’s true! The relationship between trim and fuel efficiency stems from the way trim affects a ship’s resistance in water. An optimally trimmed vessel experiences reduced hull resistance, which translates directly into lower fuel consumption.

Consider this: a large container ship might burn hundreds of tons of fuel per day. If optimizing the trim reduces fuel consumption by just 2%, the savings over a year could amount to millions of dollars. This economic incentive has driven significant research and innovation in trim optimization techniques.

Speed Optimization Through Trim Management

Speed and trim share an intricate relationship. The optimal trim for maximum speed often differs from the trim that yields the best fuel efficiency. Naval architects and ship operators must balance these factors based on operational requirements.

For instance, a vessel might adopt a slight trim by stern to achieve higher speeds, as this can reduce bow wave resistance. However, this same trim might not be ideal for fuel efficiency at lower speeds. The art of trim management lies in finding the sweet spot that aligns with the vessel’s current operational needs.

Navigational Impacts of Ship Trim

Beyond efficiency, trim significantly influences a vessel’s navigational characteristics. Let’s navigate through the ways trim affects maneuverability and operations in shallow waters.

Maneuverability and Trim

A ship’s trim condition directly impacts its turning radius and responsiveness to rudder commands. Generally, a trim by stern improves maneuverability by increasing the submerged area of the rudder and propeller. This proves particularly advantageous in tight navigational situations, such as port entries or canal transits.

However, excessive trim by stern can lead to decreased directional stability, making the vessel more susceptible to yaw motions. Ship captains must skillfully balance these factors to ensure optimal control in various sea conditions.

Trim Considerations in Shallow Waters

Operating in shallow waters presents unique challenges, and trim plays a crucial role in navigating these situations safely. A vessel trimmed by bow might risk grounding its forward section, while excessive stern trim could lead to propeller damage in shallow areas.

Smart trim management becomes especially critical when navigating depth-restricted channels or approaching shallow ports. Captains and pilots must constantly adjust trim to maintain safe under-keel clearance while preserving maneuverability.

Trim and Vessel Stability

Stability forms a cornerstone of maritime safety, and trim significantly influences a ship’s stability characteristics. Let’s examine how trim affects both longitudinal and transverse stability.

Longitudinal Stability

Trim directly impacts a vessel’s longitudinal stability, which refers to its resistance to pitching motions. A ship with optimal trim distributes its weight more evenly along its length, improving its ability to maintain level when subjected to longitudinal forces like waves or cargo shifts.

Proper longitudinal stability ensures comfort for passengers and crew, protects cargo from damage, and enhances overall seaworthiness. Naval architects carefully calculate the ideal trim conditions to maximize longitudinal stability across various loading scenarios.

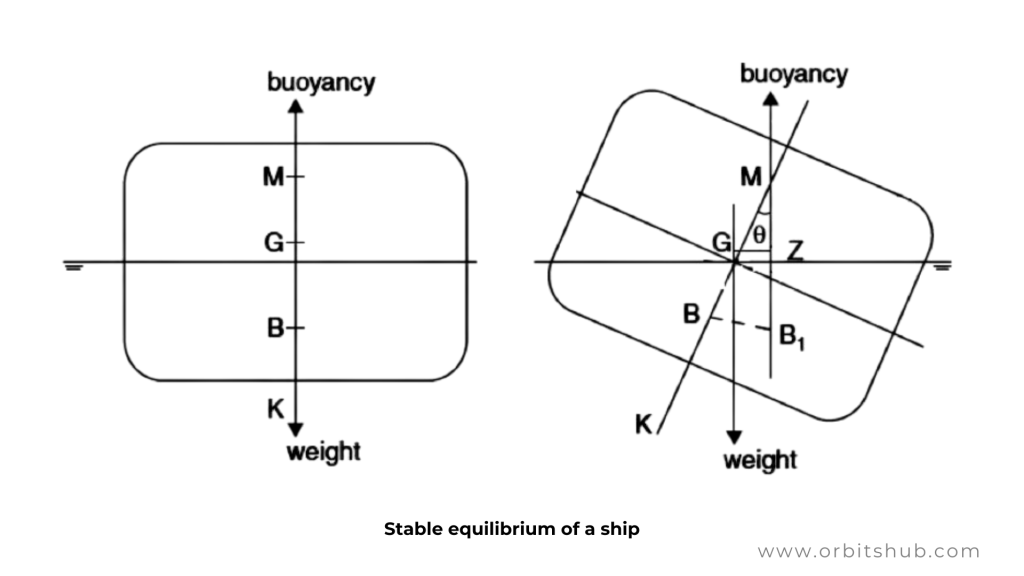

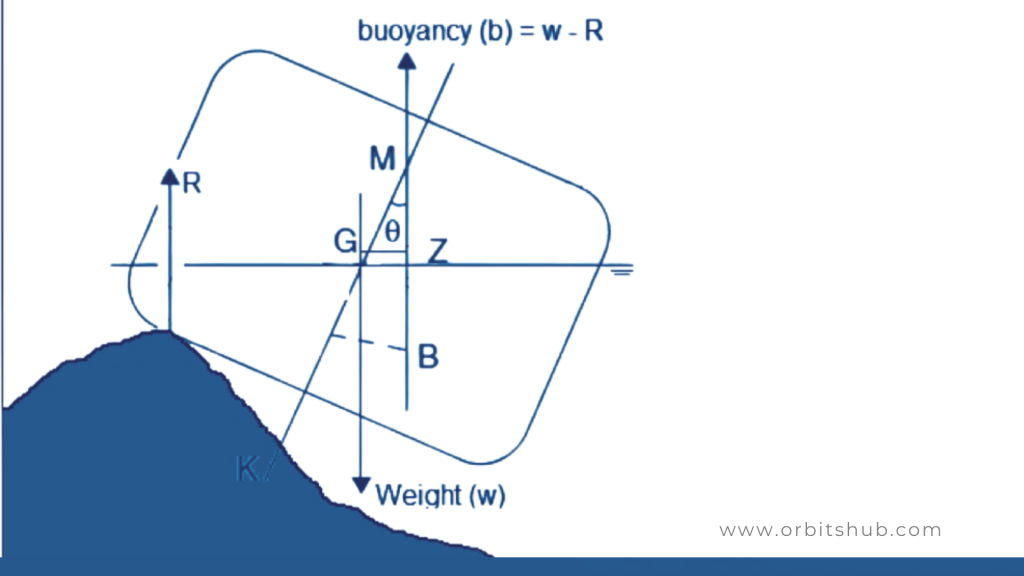

Transverse Stability

While trim primarily affects longitudinal characteristics, it also indirectly influences a ship’s transverse stability. Excessive trim in either direction can alter the vessel’s metacentric height, a key indicator of its ability to right itself when heeled.

For example, significant trim by stern might raise the center of gravity, potentially reducing transverse stability. Ship operators must remain vigilant about these interconnected effects to ensure overall vessel safety.

Modern Trim Optimization Techniques

Advancements in technology have revolutionized trim management, allowing for more precise and dynamic optimization. Let’s explore some cutting-edge approaches to trim control.

Dynamic Trim Control Systems

Modern vessels increasingly employ dynamic trim control systems. These sophisticated setups use real-time data from various sensors to continuously adjust the ship’s trim for optimal performance.

Such systems might utilize controllable flaps, adjustable ballast tanks, or even active fin stabilizers to fine-tune the trim. The result? Vessels can maintain ideal trim conditions across changing sea states, cargo distributions, and operational requirements.

AI and Machine Learning in Trim Management

Artificial Intelligence (AI) and Machine Learning (ML) have emerged as game-changers in trim optimization. These technologies analyze vast amounts of historical and real-time data to predict optimal trim settings for specific conditions.

AI-driven trim management systems can account for factors like weather patterns, route characteristics, and cargo configurations to suggest trim adjustments that maximize efficiency and safety. As these systems continue to learn and evolve, they promise to unlock new levels of vessel performance optimization.

Environmental Considerations

Trim management is a key part of making the maritime business less harmful to the environment at a time when people are becoming more aware of it. Let’s examine how proper trim contributes to sustainability efforts.

Trim’s Role in Reducing Emissions

Optimized trim directly translates to reduced fuel consumption, which in turn lowers a vessel’s emissions. With international regulations like the IMO’s carbon intensity indicator (CII) coming into force, efficient trim management becomes a key strategy for shipowners to meet environmental targets.

By maintaining optimal trim conditions, ships can significantly reduce their carbon dioxide, sulfur oxide, and nitrogen oxide emissions. This not only helps comply with regulations but also contributes to the broader goal of maritime sustainability.

Ballast Water Management and Trim

Trim adjustments often involve the use of ballast water, which carries its own environmental implications. Ballast water discharge has become a major ecological issue because it brings in invasive species. Modern methods for optimizing trim try to use as little ballast water as possible while still getting the best performance. This method not only makes things more efficient, but it also lowers the chance of damaging sensitive marine environments.

The Future of Ship Trim Technology

As we sail into the future, trim technology continues to evolve at a rapid pace. Emerging trends point towards even more sophisticated and integrated trim management systems.

Innovations on the horizon include:

- Autonomous trim control: Future ships might adjust their trim automatically based on AI predictions and real-time environmental data.

- Holistic performance optimization: Trim management will likely become part of broader vessel optimization systems that consider factors like route planning, weather routing, and energy management.

- Advanced hull designs: Naval architects are developing hull forms that maintain optimal trim across a wider range of operating conditions, reducing the need for constant adjustments.

- Integration with renewable energy systems: As ships increasingly adopt renewable energy sources like wind and solar, trim management will evolve to optimize performance with these hybrid propulsion setups.

Ship trim, once a matter of intuition and experience, has transformed into a science driven by data, technology, and environmental consciousness. As the maritime industry navigates the challenges of efficiency, safety, and sustainability, optimal trim management stands as a powerful tool in the captain’s arsenal.

Related FAQs

What is ship trim and why is it important?

Ship trim refers to the balance or orientation of a ship in the water, determined by the distribution of weight along its length. It is important because it impacts a vessel’s stability, maneuverability, fuel efficiency, and overall performance.

How does ship trim affect stability?

Ship trim plays a crucial role in maintaining a ship’s stability. A well-trimmed ship is more resistant to external forces like waves and winds, reducing the risk of capsizing or listing and providing a safer experience for crew and passengers.

How does ship trim affect maneuverability?

Ship trim is a critical factor in maneuverability. An optimal trim allows for smoother turns and improved handling, making the ship more responsive to helm commands. This is particularly important in busy harbors, narrow waterways, and emergency situations.

What is the impact of ship trim on fuel efficiency?

Ship trim significantly affects fuel efficiency. By achieving an optimal trim, ships can reduce fuel consumption and increase performance. Improper trim creates additional resistance in the water, leading to higher fuel consumption. Maintaining an ideal trim helps reduce drag and enhances speed and efficiency.

How is ship trim optimized and what are the challenges?

Ship trim optimization involves techniques such as ballasting and the use of automated systems. Ballasting redistributes water within the ship’s ballast tanks to adjust the trim. Automated systems utilize sensors, data analysis, and complex algorithms to continuously monitor and adjust the vessel’s trim in real-time. Challenges include cargo loading/unloading, changing environmental conditions, and specialized trim considerations for different types of vessels.