Aircraft fuel tank capacity is a fundamental aspect of aviation that directly impacts flight operations, safety, and efficiency. Accurate measurement of fuel capacity ensures that aircraft can complete their planned journeys safely and economically. The significance of fuel tank capacity measurements, the different approaches taken to get these numbers, and the variables that could influence precision are all topics that will be covered in this educational article.

The Basics of Aircraft Fuel Tanks

Types of Aircraft Fuel Tanks

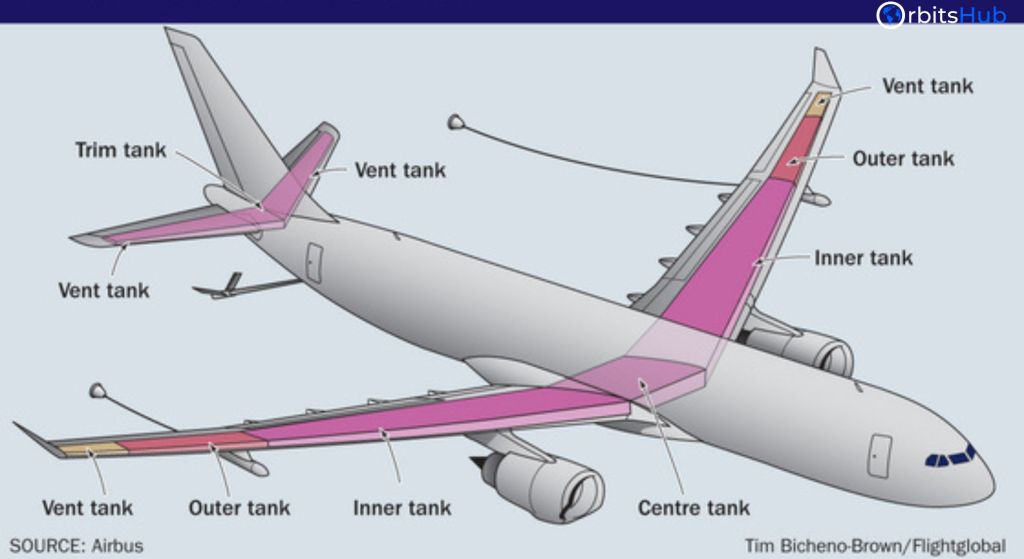

Aircraft fuel tanks come in several types, each designed to meet specific requirements:

- Integral Fuel Tanks: Built into the aircraft’s wings or fuselage, integral tanks use the aircraft structure to contain fuel.

- Bladder Fuel Tanks: Durable, detachable containers made of rubber or nylon that are simple to swap out or clean.

- Tip Tanks: These tanks help improve aerodynamic stability at the wingtips.

- Auxiliary Tanks: Additional tanks used to extend the aircraft’s range.

Importance of Accurate Fuel Measurements

Accurate fuel measurements are crucial for several reasons:

- Safety: Ensuring enough fuel for the journey, including reserves for emergencies.

- Efficiency: Optimizing fuel load to balance weight and performance.

- Cost Management: Reducing unnecessary fuel consumption and costs.

Methods of Measuring Aircraft Fuel Tank Capacity

Dipsticks and Fuel Gauges

Dipsticks

These Dipsticks are one of the simplest and oldest methods of measuring fuel levels. They involve a calibrated stick inserted into the fuel tank to measure depth. While dipsticks are reliable, they require manual effort and are unsuitable for all aircraft types.

Fuel Gauges

Fuel gauges are more advanced and commonly used in modern aircraft. They provide real-time fuel level readings, which can be analogue or digital. These gauges are calibrated to ensure accuracy and are essential to the cockpit instrumentation.

Fuel Flow Meters

Fuel flow meters measure the rate at which the engine consumes fuel. They estimate the fuel tank capacity by calculating the total fuel flow over time, which is beneficial for monitoring fuel usage during flight.

Electronic Fuel Quantity Indicating Systems (EFQIS)

EFQIS are sophisticated systems that use sensors to measure the fuel level in each tank. These systems provide accurate and real-time data to the pilot and are integrated with the aircraft’s onboard computer systems.

Capacitance Probes

Capacitance probes are commonly used in EFQIS. They measure the fuel level based on the capacitance between two electrodes immersed in the fuel. The capacitance changes with the fuel level, providing an accurate measurement.

Volume Measurement Techniques

Direct Volume Measurement

Direct volume measurement involves filling the tank to a known capacity and using that as a reference. This method is accurate but time-consuming and is typically used during aircraft manufacturing or significant maintenance.

Displacement Methods

Displacement methods measure the fuel volume displaced by an object submerged in the tank. This precise technique requires specialized equipment and is not commonly used in everyday operations.

Factors Affecting Fuel Tank Capacity Measurements

Temperature

The fuel volume strongly correlates with temperature variations, including thermal expansion and contraction. Fuel measurements must account for temperature variations to ensure accuracy.

Altitude

Altitude affects fuel density and volume. Higher altitudes can lead to reduced fuel density, impacting the accuracy of fuel measurements.

Fuel Type

Different types of fuel have varying densities and properties. Aviation gasoline (AvGas) and jet fuel (Jet-A) require different calibration and measurement techniques.

Aircraft Design

The design and shape of the aircraft fuel tanks can influence measurement accuracy. Irregularly shaped tanks may have varying fuel levels at different points, requiring precise calibration.

Advanced Technologies in Aircraft Fuel Measurement

Ultrasonic Fuel Sensors

One way to measure fuel levels is ultrasonic sensors, which employ sound waves. Because they are less sensitive to variations in fuel type and temperature, the readings they produce are reliable.

Laser-Based Systems

Laser-based systems use laser beams to determine fuel levels. Modern aircraft are increasingly integrating them for their high precision.

Internet of Things (IoT) Integration

Fuel levels can be monitored by integrating the Internet of Things and data collected in real time. These systems can also improve fuel management efficiency and predictive analytics.

Challenges in Measuring Aircraft Fuel Tank Capacity

Calibration

Regular calibration of fuel measurement systems is essential to maintain accuracy. This process involves adjusting the sensors and gauges for any changes or discrepancies.

Maintenance

Fuel measurement systems require regular maintenance to ensure correct operation. Issues such as sensor degradation or mechanical wear can affect accuracy.

Human Error

Manual measurements, such as using dipsticks, are prone to human error. Ensuring proper training and procedures can help minimize these errors.

Best Practices for Accurate Aircraft Fuel Measurement

Regular Calibration and Maintenance

Ensuring regular calibration and maintenance of all measurement systems is crucial for accuracy. This includes routine checks and servicing as per manufacturer guidelines.

Training and Standard Operating Procedures

Proper training for personnel involved in fuel measurement is essential. To ensure reliability and precision, you must establish and adhere to standard operating procedures.

Use of Advanced Technologies

Integrating advanced measurement technologies like Electronic Fuel Quantity Indicating Systems and ultrasonic sensors can significantly enhance accuracy and reliability.

Accurately measuring aircraft fuel tank capacity is a critical aspect of aviation that ensures safety, efficiency, and cost management. Aviation professionals can make informed decisions and maintain optimal fuel management by understanding the various methods and technologies used to measure fuel levels and the factors that can affect these measurements.

At OrbitsHub, we provide comprehensive aviation consultancy services, including expert guidance on fuel management and measurement techniques.

Explore the OrbitsHub Website for more insights and expert advice on aviation and maritime consultancy services.