A ship anchor is a device to hold a ship or a boat in the water. It is usually made of metal and has one or more flukes or arms that dig into the seabed or the riverbed when the anchor is lowered. The anchor is connected to the ship by a chain or a rope called the anchor cable or the anchor rode. Anchors are essential for the safety and stability of ships, especially when they need to stop, park, or moor in a specific location. Anchors can also help ships avoid drifting due to wind, waves, or currents or maintain a fixed position for fishing, diving, or other activities. There are many anchors, each with different designs, sizes, and functions. Some of the most common types of anchors are:

| Anchor Type | Suitable Environment | Key Characteristics |

|---|---|---|

| Plow (CQR) | Sand, mud, gravel | Versatile, strong hold, resets well, sturdy construction, hinged shank for various seabed types |

| Fluke (Danforth) | Soft mud, sandy bottoms | High holding power-to-weight ratio, lightweight, compact, sharp flukes for easy penetration |

| Bruce (Claw) | Most seabed types except very hard rock | Good in heavy weed/kelp, sturdy design, self-aligns and resets |

| Mushroom | Soft seabeds like mud or silt | Low holding power, relies on weight and suction, ideal for permanent moorings |

| Admiralty (Fisherman’s) | Rocky, coral, hard seabeds | Strong hold in rough conditions, traditional design, hooks into rocks and vegetation |

| Grapnel | Rocky or reef-filled environments | Quick deployment, lightweight, compact, ideal for small crafts, poor performance in soft sediments |

| Delta | Mud, sand, gravel | Strong holding power, quick setting, self-resetting, versatile |

| Box | Soft mud, sand, gravel | Heavy weight and large surface area prevent movement, easy deployment and retrieval |

Plow Anchor

A plow anchor, also known as a CQR (Coastal Quick Release) anchor, has a single, large, and heavy fluke that resembles a plow. The fluke can pivot on a shank, which allows the anchor to adjust to different angles and orientations when it hits the bottom. The plow anchor is designed to dig deep into the seabed and provide a strong holding power.

Design and Construction

The Plow Anchor, often referred to by the brand name CQR (Coastal Quick Release), is designed to resemble a traditional farmer’s plow. Its robust construction usually involves high-grade galvanized or stainless steel. The anchor includes a plow-shaped head attached to a shank; some models feature a hinge at the shank and head junction, allowing the head to articulate relative to the shank, which aids in setting and maintaining a hold in various seabed conditions.

Operating Principle

The plow-shaped head of this anchor is engineered to dig into the seabed as tension is applied through the anchor rode (line or chain). This digging action is facilitated by the sharp, sturdy tip of the plow head, which can cut into different types of seabed materials. Once set, the anchor’s broad surface area helps maintain a secure hold by resisting sideways motion and lifting.

Performance and Suitability

There are many types of bottom, such as sand, mud, and gravel, and plow anchors are known for being able to hold in all of them. They are particularly valued for their ability to reset themselves if dislodged due to changing wind or tide conditions. However, their performance might be compromised in very rocky or heavily vegetated areas where the plow cannot easily penetrate.

Advantages:

- Versatile: Effective in most types of seabeds, with good resetting capabilities.

- Sturdy Construction: Durable and robust, suitable for heavier boats and challenging conditions.

- Articulating Design: Some models feature a hinged shank that helps the anchor adapt to changes in pull direction, enhancing holding power.

Limitations:

- Weight: Generally heavier than fluke anchors, requiring more effort to handle and deploy.

- Cost: Can be more expensive due to its construction and materials.

- Size: Larger and bulkier, requiring more storage space.

Applications

Plow anchors are favored by cruising and offshore boats due to their reliability and strong performance across various environments. They are suitable for boats that require a dependable primary anchor capable of adapting to different anchoring conditions and seabeds.

Fluke Anchor

A fluke anchor, also known as a Danforth anchor, is a type of anchor that has two flat and triangular flukes that are attached to a stock at a right angle. The stock helps to keep the flukes parallel to the bottom when the anchor is lowered. The flukes have sharp edges that dig into the seabed, providing a high holding power relative to the anchor’s weight.

Design and Construction

The Fluke Anchor, commonly referred to as a Danforth, features a unique design characterized by its two large, flat, and triangular flukes attached to a central shank. Most of the time, this anchor is made of galvanized or stainless steel, which makes it strong and resistant to rust and rusting. The design is both lightweight and compact, making it easy to handle and store, which is particularly advantageous for smaller boats and vessels.

Operating Principle

The flukes of a Danforth anchor are engineered to dig into the seabed, using their broad surface area to create resistance. When the anchor lands on the seabed, the flukes pivot downward as the boat pulls on the anchor, allowing the sharp edges of the flukes to dig or bury into the bottom sediment. The more the pull or tension from the anchor line, the deeper the flukes dig into the seabed.

Performance and Suitability

Fluke anchors offer exceptional holding power in soft mud and sandy bottoms, where the flukes can easily penetrate. The design allows for a high holding power-to-weight ratio, meaning that lighter anchors can hold a boat securely under favorable conditions. However, their performance is less effective in rocky, grassy, or heavily weeded bottoms, as the flukes struggle to penetrate and may instead slide over the surface.

Advantages:

- High Holding Power: Effective in ideal conditions, providing strong holding capacity relative to its weight.

- Compact and Lightweight: Easy to handle, store, and deploy, making it ideal for smaller boats.

- Cost-Effective: Generally less expensive than many other types of anchors.

Limitations:

- Variable Performance: Performance can vary significantly with changes in seabed composition.

- Not Suitable for All Conditions: Less effective in rocky or vegetated areas where it cannot easily penetrate the ground.

Applications

Due to its design and effectiveness in specific conditions, the Fluke Anchor is a popular choice among small to medium-sized boats, particularly for recreational and fishing activities. It’s also a favored choice for auxiliary or secondary anchors, easily stowed and deployed as needed.

Bruce Anchor

A claw anchor, also known as a Bruce anchor, is a type of anchor that has three curved and pointed claws that are attached to a shank. The claws are designed to grip the seabed and provide moderate holding power in various conditions. The claw anchor can also self-align and reset itself if dislodged or dragged.

Design and Construction

The Bruce Anchor, originally designed in the 1970s by Peter Bruce from the Isle of Man, is recognized for its distinct claw-like shape. This design consists of a solid, one-piece construction that typically uses galvanized or stainless steel. The anchor has three claws that are intended to maintain contact with the seabed, providing stability and a high holding power under various conditions.

Operating Principle

The Bruce Anchor works on the principle of maintaining constant contact with the seabed through its three claws. Each claw is designed to dig into the seabed as the boat moves, ensuring that at least one claw is always embedded. This design allows for excellent setting behavior and helps the anchor reposition itself if the direction of pull changes, thereby maintaining a firm hold.

Performance and Suitability

Bruce anchors are known for their reliability in most seabed types, including mud, sand, and shingle. However, they may have difficulties in very hard, rocky conditions where the claws cannot easily penetrate. Their robust construction makes them particularly effective in areas with heavy weed or kelp, as the claws can grip well in such environments.

Advantages:

- Immediate Setting: Often sets rapidly and effectively without much drag.

- Sturdy Design: Resistant to breaking free once set, providing consistent performance.

- Low Maintenance: Simple, durable construction with few moving parts reduces the likelihood of malfunction or damage.

Limitations:

- Performance in Rocks: Not ideal for use in hard, rocky bottoms where penetration is critical.

- Bulk and Weight: Can be heavy and cumbersome, making handling and storage challenging on smaller vessels.

Applications

The Bruce Anchor is popular among boaters in need of a reliable, general-purpose anchor that performs well in most conditions except the rockiest seabeds. It is especially favored on larger boats and in permanent mooring applications where its dependable hold and ease of use are particularly valued.

Mushroom Anchor

A mushroom anchor, also known as a mooring anchor, is a type of anchor that has a round and convex shape that resembles a mushroom. The mushroom anchor relies on its weight and shape to create a suction effect with the seabed, providing a low holding power. The mushroom anchor is usually buried in the seabed and attached to a permanent mooring buoy or a floating dock.

Design and Construction

The Mushroom Anchor gets its name from its distinct shape, resembling a mushroom cap. This anchor is typically made from heavy metal and is designed for permanent moorings. The wide, round cap and relatively short stem allow the anchor to embed deeply into soft seabed materials like mud or silt. The design ensures that the anchor buries itself over time, increasing its holding power due to both its weight and the suction it creates with the seabed.

Operating Principle

Mushroom anchors operate primarily through their weight and the suction they create with the seabed. When deployed, the cap buries itself into the mud or silt, creating a vacuum effect that makes it difficult to dislodge. Over time, the anchor can become even more secure as sediment builds over it.

Performance and Suitability

Mushroom anchors are best suited for soft seabeds such as mud or silt where they can sink and create a secure hold. They are not effective on rocky or hard surfaces where they cannot easily penetrate or create suction. Their performance is highly dependable in the environments for which they are designed, particularly in sheltered waters where severe weather and strong currents are less common.

Advantages:

- Permanent Solution: Ideal for long-term moorings, particularly for buoys or dock anchoring.

- Low Profile: The design is less obtrusive and does not significantly disrupt the seabed or marine life once settled.

- Increasing Holding Power: Over time, its holding power increases as it buries deeper and sediment covers it.

Limitations:

- Limited Seabed Compatibility: Only effective in soft seabeds and not suitable for varied anchoring conditions.

- Weight: Generally very heavy, making handling and deployment challenging without proper equipment.

Applications

Mushroom anchors are commonly used for mooring buoys, floating docks, and in marinas for permanent placements. They are also a popular choice for conservation projects and in marine protected areas where minimal disruption to the seabed is crucial.

Admiralty Anchor (Fisherman’s Anchor)

The Admiralty Anchor, also known as the Fisherman’s Anchor, is one of the oldest types of anchors and is easily recognized by its traditional design. It features a heavy metal construction with a central shank and two large, curved arms ending in flukes, with a crosspiece (or stock) at the top. This anchor is typically made from forged steel or iron, contributing to its substantial weight and robustness.

Operating Principle

The Admiralty Anchor operates by catching and hooking into the seabed with its flukes. The stock at the top of the anchor ensures that one of the flukes points downward, allowing it to dig into the seabed. The anchor’s weight helps it drop and settle quickly, while the design of the arms allows it to snag onto rocks, coral, or other rugged seabed features.

Performance and Suitability

This type of anchor is particularly effective on rocky, coral, and hard seabeds where modern anchors might struggle to gain a foothold. It can also perform well in weeds or kelp, as the arms can hook into vegetation. However, its effectiveness is reduced in soft mud or sand where penetration is crucial for holding power.

Advantages:

- Strong Hold in Rough Conditions: Excellent performance in rocky and uneven seabeds.

- Durable: Robust construction ensures longevity and resistance to bending or breaking.

- Versatile: Can be used in a variety of marine environments, particularly where other anchors may fail.

Limitations:

- Heavy and Bulky: Difficult to handle and requires significant storage space.

- Slow to Deploy and Retrieve: Due to its weight and size, deploying and retrieving the Admiralty Anchor can be challenging without mechanical assistance.

- Limited Holding Power in Soft Sediments: Not ideal for use in fine sand or mud.

Applications

The Admiralty Anchor is favored for use in challenging marine environments where a secure hold is paramount, such as in coastal and offshore fishing, shipping, and in historical vessels that maintain traditional equipment. It’s also used in permanent installations where its ability to secure itself in tough conditions is a significant advantage.

Grapnel Anchor

The Grapnel Anchor is relatively simple in design, resembling a grappling hook. It typically consists of several tines or flukes, usually four, attached to a central shank. This type of anchor is often made from galvanized steel or other durable metals, making it both lightweight and sturdy. Due to its compact size and collapsible tines on some models, it is easily storable, making it popular among small boat owners and kayakers.

Operating Principle

The operation of the Grapnel Anchor relies on its tines catching onto seabed features such as rocks, tree roots, or other underwater structures. When the anchor is thrown overboard, the tines snag onto these features, holding the vessel in place. The more the boat pulls, the more the tines dig in or catch, enhancing the anchor’s grip.

Performance and Suitability

Grapnel anchors are particularly effective in rocky or reef-filled environments where their tines can easily catch on irregularities in the seabed. They are less effective in sandy or muddy conditions where penetration into the seabed is required for stability, as the tines do not provide sufficient surface area for digging in.

Advantages:

- Quick Deployment: Easy to throw and set, particularly in shallow waters or when precise positioning is needed.

- Compact and Lightweight: Ideal for small boats, kayaks, and temporary anchorage.

- Effective in Rocky Areas: Excellently suited for anchoring in areas with many crevices and obstructions.

Limitations:

- Limited Holding Power: Not suitable for large vessels or in strong currents and high winds due to its relatively low holding power.

- Poor Performance in Soft Sediments: Struggles to maintain a hold in sandy or muddy bottoms.

- Potential for Snagging: While it can secure well in rocky areas, it also has a higher risk of becoming irretrievably snagged.

Applications

Grapnel anchors are commonly used for small craft, including dinghies, kayaks, and canoes. They are also popular in recreational activities where temporary anchorage is required, such as during rock fishing or when anchoring near shorelines for picnics or swimming.

Due to its design and functionality, the Grapnel Anchor is a practical choice for specific scenarios, particularly where lightweight and easy-to-deploy options are beneficial. It is especially useful for adventurers and small craft enthusiasts who need a reliable, easy-to-handle anchoring solution in suitable environments.

Delta Anchor

The Delta Anchor, a variation of the plow anchor, is known for its distinctive triangular shape which enhances its seabed penetration capabilities. Made from high-grade galvanized or stainless steel, the Delta Anchor features a solid, one-piece design that ensures strength and durability. Its plow-shaped tip and large fluke area enable it to set quickly and dig deeply into a variety of seabed types.

Operating Principle

The Delta Anchor operates by utilizing its weighted tip and broad flukes to dig into the seabed as tension is applied to the anchor rode. Its design ensures that the anchor buries itself efficiently upon dragging, providing substantial holding power. The anchor’s shape allows it to reset quickly if it becomes dislodged, which is particularly valuable in changing conditions.

Performance and Suitability

Delta anchors are highly versatile, performing well in most types of seabeds, including mud, sand, and gravel. They are less effective on rocky bottoms or in very hard clay, where deeper penetration is more challenging. Their reliable performance in a variety of conditions makes them a popular choice among boaters.

Advantages:

- Strong Holding Power: Provides excellent holding capacity, which is often several times the weight of the anchor itself.

- Quick Setting: Designed to set rapidly, minimizing drift and providing immediate security.

- Self-Resetting: Capable of re-embedding itself if the wind or current shifts the boat.

Limitations:

- Heavier Weight: While offering robust performance, its solid construction makes it heavier than some other types, requiring adequate handling and storage capacity.

- Price: Typically more expensive due to its design and the materials used.

Applications

The Delta Anchor is favored for use on cruising and racing boats, as well as larger vessels that require reliable anchoring solutions. Its effectiveness in various seabed conditions and its ability to reset itself make it a valuable asset for boaters who travel in diverse environments.

The Delta Anchor’s robust design and dependable performance make it a go-to choice for many in the boating community, providing peace of mind with its strong and versatile anchoring capabilities.

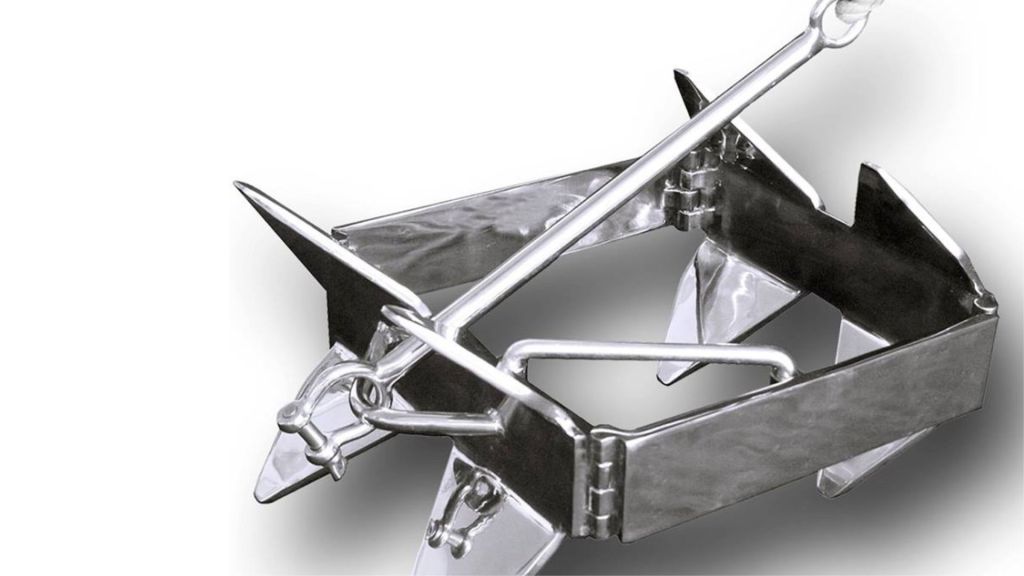

Box Anchor

The Box Anchor is a uniquely designed anchor, distinct from traditional types due to its foldable box-like structure. This anchor typically consists of several large flat panels connected by pivoting joints, allowing it to collapse for storage and expand for use. Made from galvanized or stainless steel, the Box Anchor is designed to maximize contact with the seabed across its large surface area, enhancing its holding power.

Operating Principle

When deployed, the Box Anchor lands on the seabed and lays flat, allowing its panels to press into the sediment. Unlike traditional anchors that require digging or penetration, the Box Anchor relies on its heavy weight and broad surface area to resist movement. This design prevents the anchor from needing to burrow into the seabed to achieve stability, making it effective even in soft or shifting sediments.

Performance and Suitability

The Box Anchor performs exceptionally well in a variety of seabed types, including soft mud, sand, and gravel. Its design allows it to hold securely even where other anchors might fail, such as in shifting sands or silty bottoms. However, it may be less effective on very rocky or compacted surfaces where its panels cannot create sufficient resistance.

Advantages:

- Versatile Holding Ability: Effective across diverse seabed conditions without the need for precise positioning.

- Easy Deployment and Retrieval: The anchor’s foldable design makes it straightforward to deploy and retrieve, reducing the effort involved significantly.

- No Need for Chain: Does not typically require a heavy chain to aid in anchoring, as its design allows it to lay flat and maintain a hold independently.

Limitations:

- Bulkiness: Even though it folds, the anchor is still bulky compared to traditional designs and requires adequate storage space.

- Weight: It is generally heavier, which might be a consideration for smaller vessels.

Applications

The Box Anchor is ideal for recreational boaters and is particularly popular among pontoon boat owners, as well as those engaging in activities in lakes and rivers where the seabed conditions can vary widely. Its ability to maintain a hold without specific seabed penetration makes it highly effective for leisure activities where quick anchoring and movement are common.

Maintenance and Care of Ship Anchors

Ship anchors last longer and work better if they are correctly maintained. Key practices include:

- Inspection: Regularly check for wear, rust, or damage.

- Cleaning: Remove marine growth, mud, and debris.

- Storage: Store properly to avoid exposure to elements; rinse with fresh water.

- Lubrication: Keep moving parts well-lubricated.

- Replacement: Replace anchors or components when worn or damaged.

Innovations in Anchor Deployment Systems

Modern deployment systems enhance anchoring efficiency and reliability through the following:

- Hydraulic Winches: Power-assisted deployment and retrieval.

- Automatic Anchor Windlasses: Automates the anchoring process.

- Remote Control Systems: Control anchors from various locations on the ship.

- GPS Integration: Precisely control anchor position using GPS.

- Real-Time Monitoring: Provides real-time data on anchor status and seabed conditions.

History of Ship Anchors

The history of ship anchors dates back to ancient times, when people used various objects, such as stones, logs, or baskets filled with sand, to anchor their boats or rafts. The Egyptians probably made the first metal anchors, who used iron hooks with wooden stocks to anchor their ships on the Nile River. The Greeks and the Romans improved the design of the anchors by adding flukes and rings to the hooks and using lead or bronze to make them heavier and more robust.

The medieval anchors were similar to the ancient ones but had more flukes, were more extensive, and were heavier. The anchors were also decorated with symbols or inscriptions, such as crosses, coats of arms, or names of ships or owners. The anchors were often use as symbols of authority, power, or protection and were sometimes display on the walls or gates of castles, churches, or towns.

The modern ship anchors were develop in the 19th and 20th centuries, when new materials, such as steel, and new technologies, such as steam engines and hydraulic winches, were introduce. The anchors became more efficient, reliable, and versatile and could be used for ships, seabeds, and situations. Some of the most influential inventors of modern anchors were James R. Stockless, Richard Danforth, Peter Bruce, and Geoffrey Ingram Taylor.

How to Choose the Right Anchor for Your Ship

Size, weight, water type, depth, weather, sea conditions, and personal preferences are just a few of the numerous variables that go into making an informed decision when selecting an anchor for your ship. Here are some tips to help you choose the suitable anchor for your boat:

- Know your ship’s characteristics: The first step is to know your ship’s characteristics, such as the length, beam, draft, displacement, and windage. These considerations dictate the anchor’s size, weight, and dimensions of the anchor road or cable. Based on your ship’s specifications, you can determine the anchor size and weight using online calculators or charts.

- Know your water type and depth: The second step is to establish water type, depth, bottom composition, tide range, and temperature. These factors affect anchor cable or rode type, design, scope, and scope ratio. For varied anchor types and seabeds, the scope—anchor cable or rode length to water depth—is advised. Use online resources or charts to choose an anchor type and design for your water type and depth.

- Know your weather and sea conditions: The third step is to know your weather and sea conditions, such as the wind speed and direction, the wave height and frequency, and the current strength and direction. These factors will determine the holding power and stability of the anchor that you need, as well as the safety and security of your ship and crew. Using internet tools or apps, you can plan by checking the weather and sea conditions at your anchoring spot.

- Know your anchoring needs and preferences: Define your anchoring needs and preferences—time, frequency, purpose, activity, money, and equipment space—in the third stage. These characteristics determine anchor number, kind, quality, and ease. Online reviews and brand comparisons might assist you pick an anchor.

The Future of Ship Anchors and Anchor Technology

Ship anchors and anchor technology have come a long way since ancient times, when people used stones, logs, or baskets to anchor their boats or rafts. Today, ship anchors and anchor technology are constantly evolving and improving thanks to materials, engineering, and innovation advances. Here are some of the trends and developments that are shaping the future of ship anchors and anchor technology:

- Bright anchors: Smart anchors track and report position, orientation, movement, condition, water depth, temperature, and quality via sensors, cameras, or GPS devices. Remotely modify or recover bright anchors using wireless or satellite connections. Bright anchors improve efficiency, accuracy, and safety and give ship owners and operators valuable input.

- Eco-friendly anchors: Eco-friendly anchors reduce or eliminate seabed, marine life, and ecosystem harm. Eco-friendly anchors might be built of biodegradable or recyclable materials like wood, bamboo, or plastic or include features that reduce drag, noise, or corrosion. Eco-friendly anchors can collect or filter water, plant or seed the seafloor, or shelter marine life.

- Hybrid anchors: Hybrid anchors combine the features of two or more anchors to build a new or enhanced anchor. The shape, size, weight, or material of the fluke, shank, stock, or anchor mechanism, system, or device can improve hybrid anchor performance, adaptability, or convenience. The mode, method, or purpose of hybrid anchors can also broaden or diversify their use.

Ship anchors are essential devices that help ships stay in the water. There are many anchors, each with different designs, sizes, and functions. Some of the most common anchors are plow, fluke, claw, and mushroom anchors. Ship anchors originated when people used various things to anchor their boats or rafts. The modern anchors were develop in the 19th and 20th centuries when new materials and technologies were introduce.

Related FAQs

What is a ship anchor?

A ship anchor is a heavy metal object designed to hold a ship or boat in place by embedding it into the seabed. It’s crucial maritime equipment to prevent a vessel from drifting away.

How does a ship anchor work?

When dropped overboard, the anchor sinks to the seabed and catches onto the bottom surface, such as sand, mud, or rock. The chain or rope attached to the anchor provides the necessary tension to keep the ship stationary against currents or winds.

What type of anchor is best for soft seabeds like mud or silt?

The Mushroom Anchor is best suited for soft seabeds such as mud or silt. Its design allows it to create suction with the seabed, increasing its holding power over time. It’s ideal for permanent moorings in sheltered areas with soft bottoms.

Which anchor should I use for a rocky seabed?

The Admiralty Anchor (Fisherman’s Anchor) is highly effective on rocky seabeds. Its heavy, rugged design and large flukes allow it to hook onto rocks and other rough surfaces, providing strong holding power in such environments.

What is the best anchor for a boat that frequently changes anchorage sites?

The Claw Anchor is particularly suitable for boats that often change anchorage sites. Its versatile design allows it to perform well in various seabed types, and its ability to reset itself if dislodged makes it ideal for dynamic conditions.

Which anchor offers the best versatility across different seabed types?

The Plow Anchor (CQR) is known for its versatility and strong holding power in a wide range of seabed types, including sand, mud, and gravel. It’s particularly valued for its ability to reset itself after being dislodged, making it suitable for varying conditions.

What anchor should I use for temporary anchorage in shallow waters?

The Grapnel Anchor is excellent for temporary anchorage, especially in shallow waters where precision is necessary. It’s lightweight, easy to deploy, and effective in rocky or reef-filled environments, making it perfect for small boats and kayaks.

Best ship anchor for small boats?

For a small boat, the Fluke (Danforth) anchor is often considered the best due to its lightweight design and strong holding power in sand and mud bottoms. It’s easy to handle and provides reliable anchorage in soft conditions. If you frequently anchor in diverse environments, the Claw (Bruce) anchor offers versatility, performing well in mud, sand, rock, and coral, though it can be bulkier. Both options are popular among small boat owners for their effectiveness and ease of use.