In the ever-evolving world of maritime trade, efficiency reigns supreme. Just like a well-oiled machine, a ship thrives on the seamless interaction of its numerous parts. The journey can only be accomplished with each component, from the enormous hull confronting the oceans to the intricate engine that propels it. This blog delves into optimizing ship and parts performance, ultimately leading to smoother journeys and a prosperous bottom line.

Navigating the Importance of Ship Performance: Ship and Parts

A ship in top condition is not just about aesthetics but safety, efficiency, and profitability. Here’s how optimizing ship performance benefits all stakeholders:

- Enhanced Safety: Avoiding failures and accidents at sea is crucial for crew, cargo, and environment safety. Regular maintenance and part replacements can help achieve this goal.

- Improved Fuel Efficiency: Improvements in fuel economy, operational costs, and environmental effects can be achieved through the optimization of hulls, propellers, and engines.

- Reduced Downtime: By proactively addressing potential issues through maintenance and part optimization, ships spend less time docked for repairs, increasing productivity.

- Boosted Profitability: Improved efficiency, reduced downtime, and lower fuel consumption significantly increase profit margins.

Optimizing the Orchestra: Key Parts and Ship Strategies

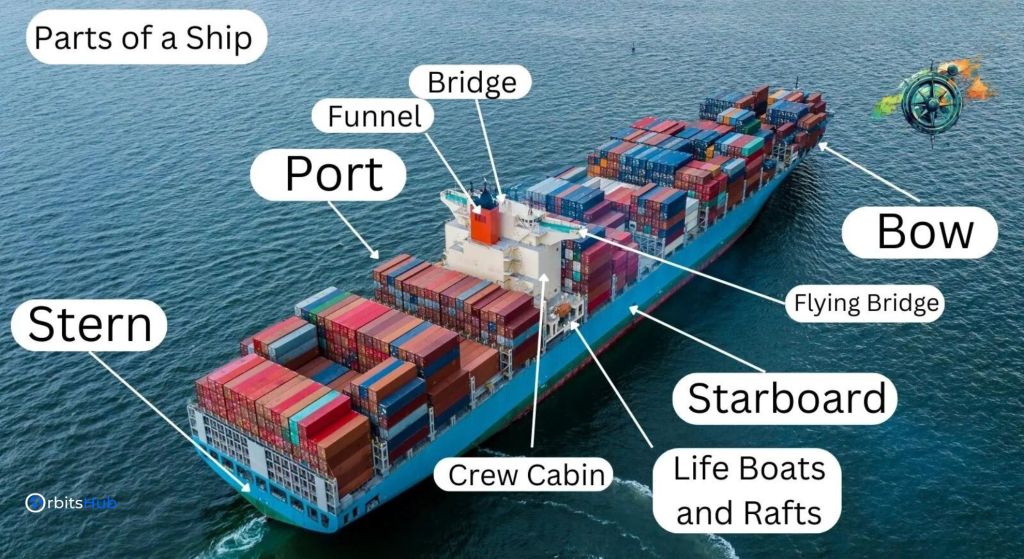

A ship is a symphony of parts, each playing a crucial role in its success. Here’s a closer look at some key components and strategies for optimization:

The Engine Room: Powering Performance

The heart of a ship, the engine room, demands meticulous attention.

- Regular servicing and maintenance: Following manufacturer recommendations for engine maintenance schedules is crucial.

- Part optimization: Using high-quality, energy-efficient parts can significantly improve fuel efficiency.

- Crew training: Investing in crew training on efficient engine operation practices can yield long-term benefits.

The Hull: Cutting Through Resistance

The hull is a ship’s armour against the sea. Here’s how to keep it performing optimally:

- Hull cleaning: Regular cleaning prevents the build-up of marine organisms that can increase drag and fuel consumption.

- Hull inspections: Regular inspections identify potential damage or corrosion for timely repairs.

- Anti-fouling coatings: These coatings deter the growth of marine life on the hull, minimizing drag.

The Bridge: Steering the Course

The bridge is the captain’s command centre, and optimizing navigation systems is vital:

- Modern navigation equipment: Utilizing advanced GPS, radar, and communication systems ensures precise navigation and efficient route planning.

- Weather monitoring: Real-time weather data allows for informed route adjustments, minimizing risks and optimizing fuel usage.

- Crew training: Investing in crew training on navigation systems and best practices fosters smooth and efficient operations.

Leveraging Technology for Peak Performance

The maritime industry is embracing the power of technology to optimize ship performance. Here’s how:

- Intelligent Monitoring Systems: Sensors can continuously monitor engine performance, fuel consumption, and other vital parameters. Data collected in real-time enables prompt identification of possible problems and implementation of corrective actions.

- Predictive Maintenance: Advanced data analytics can predict equipment failures before they occur. This allows proactive maintenance, minimizing downtime and associated costs.

- Digital Twins: Virtual simulations of different circumstances are made possible by creating digital replicas of ships. This helps optimize maintenance schedules, crew training, and route planning.

Crew Training and Spare Parts Management

Optimizing ship performance requires a collaborative effort between various stakeholders:

- Crew Training: Investing in crew training on efficient ship operation, maintenance procedures, and emergency response protocols ensures optimal performance and safety.

- Spare Parts Management: Maintaining a readily available stock of critical spare parts minimizes downtime in case of breakdowns. Efficient inventory management systems are crucial.

- Communication and Collaboration: Clear communication between crew, shoreside management, and suppliers ensures timely repairs and efficient parts procurement.

A Well-Tuned Ship is a Profitable Ship

Optimizing ship and parts performance is ongoing, but the rewards are substantial. By implementing a strategic approach to maintenance, part selection, and crew training, maritime businesses can ensure their vessels navigate the seas with maximum efficiency and profitability.

Are you ready to discover how OrbitsHub can help you get the most out of your ship and its parts? Our marine and aviation consulting experts may assist you with various tasks to make your operations more efficient and get you where you need to go faster. Contact us today, and let’s chart a course for a prosperous future!