Remembering that every part of a ship is important to its total performance is important. The rotor shaft is one of the most important parts. Between the engine and the blade, it is this part that needs to be lined up correctly for the boat to run smoothly. Propeller shaft alignment is often overlooked, but it is a key factor in ensuring that ships run efficiently without unnecessary wear and tear or energy loss.

What is Propeller Shaft Alignment?

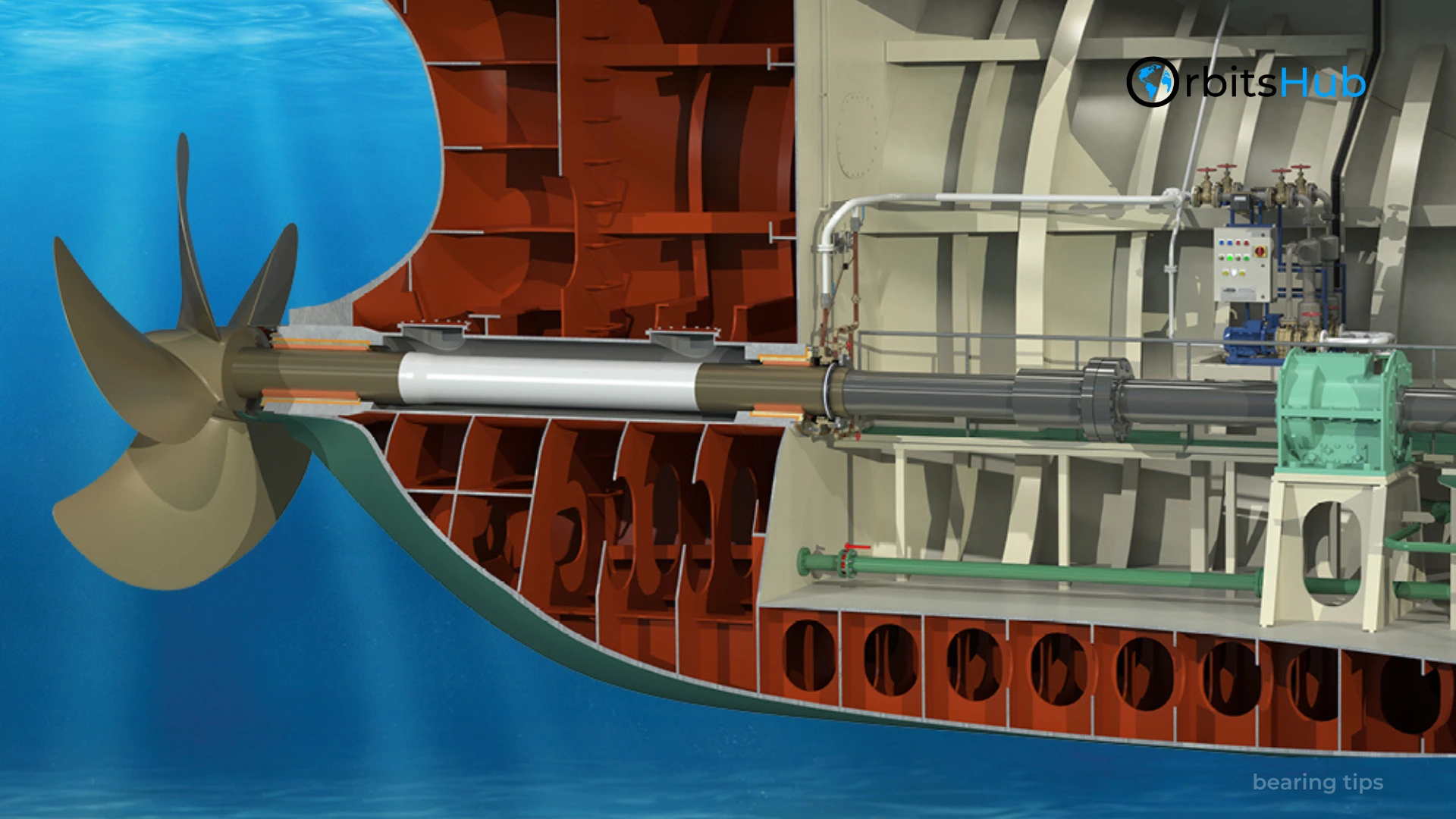

A propeller shaft is essentially a long cylindrical part that transmits mechanical power from the engine to the ship’s propeller. The alignment of the propeller shaft refers to how well this shaft is positioned in relation to the engine, the bearings, and the propeller. A misaligned shaft can result in excessive vibration, increased friction, and, in the worst cases, engine damage.

To understand this, think of the propeller shaft as the spinal cord of the ship’s propulsion system. If it’s not aligned properly, it will lead to a host of issues. Aligning the shaft involves adjusting its position and ensuring that it runs true from the engine all the way to the propeller. If the shaft is out of alignment, the bearings will wear out faster, leading to a reduced lifespan of the shaft and other connected components.

How Misalignment Affects Efficiency

A poorly aligned propeller shaft can have a ripple effect on a ship’s efficiency. To put it simply, when the shaft isn’t aligned properly, the engine has to work harder to turn the propeller, causing a number of performance problems.

One of the key issues with misalignment is increased friction. When the propeller shaft isn’t running smoothly, there’s more resistance, which makes the engine work harder and consume more fuel. This results in a direct increase in operational costs for shipping companies. A 1% increase in fuel efficiency can translate into significant savings over time.

Additionally, misalignment also leads to excessive vibrations. This not only affects the comfort of the crew and passengers but can also cause further damage to other vital parts of the ship. Over time, vibrations can weaken the structural integrity of the ship and lead to more frequent maintenance.

The Importance of Proper Alignment for Propeller Shaft Efficiency

Now that we know what happens when alignment isn’t right let’s look at what happens when alignment is right.

1. Increased Fuel Efficiency

A properly aligned propeller shaft reduces friction and allows the engine to run smoothly, which, in turn, optimizes fuel consumption. Studies have shown that even a small reduction in drag due to proper shaft alignment can result in a noticeable decrease in fuel consumption.

2. Extended Lifespan of Components

The proper alignment of the shaft ensures that there is minimal wear and tear on the bearings, seals, and other parts connected to the shaft. As a result, the lifespan of these components is extended, and the need for costly replacements or repairs is minimized. With the increased longevity of parts, shipping companies can save substantial amounts of money on maintenance costs.

3. Reduced Vibration

Vibrations are one of the primary problems caused by misalignment. These vibrations affect the comfort of the crew and passengers and can also cause significant damage to other components of the ship. Proper shaft alignment ensures that vibrations are kept to a minimum, enhancing the overall comfort on board and reducing the risk of mechanical failures.

4. Reduced Maintenance Costs

When the propeller shaft is aligned correctly, the ship experiences fewer breakdowns and maintenance issues. This means fewer trips to dry docks, reduced labor costs, and fewer spare parts required for repairs. This translates into significant savings for shipping companies, particularly those with large fleets of ships.

5. Improved Operational Performance

A well-aligned propeller shaft ensures that the engine and propeller work in harmony, improving overall operational performance. The vessel will be able to travel more efficiently, reach higher speeds, and reduce the overall strain on the engine. There will be less damage to the whole ship because of a smoother ride, which makes it more stable.

How to Ensure Proper Propeller Shaft Alignment

Now that we’ve covered the importance of propeller shaft alignment let’s take a look at how the alignment process works.

- Initial Inspection: The first step in ensuring proper alignment is to inspect the propeller shaft and associated components. One way to do this is to look for obvious signs of damage, wear, or corrosion on the shaft, bearings, and blade.

- Measurement: Precise measurement is essential to aligning the shaft properly. Specialized tools are used to measure the angles of the shaft, bearings, and propeller. These tools help determine whether there are any misalignments that need to be corrected.

- Adjustment: Once the measurements are taken, adjustments are made to correct any misalignments. This may involve adjusting the position of the engine, the shaft, or the bearings. In some cases, it may also involve replacing worn components to ensure that everything is in optimal working condition.

- Final Testing: After the alignment is adjusted, the system is tested to ensure everything is working smoothly. This step involves running the engine and observing the vibrations, temperature, and performance. If everything checks out, the ship is ready for operation.

The Role of Technology in Shaft Alignment

With advancements in technology, shaft alignment has become more precise and efficient. Traditional methods of alignment involved manual measurements and adjustments, but now, sophisticated alignment systems that use laser technology are available to measure the angles of shafts with pinpoint accuracy. This reduces human error and ensures a faster, more reliable alignment process.

Real-Life Example of the Impact of Proper Alignment

A real-life example can be seen in the case of a shipping company that conducted a thorough propeller shaft alignment process on one of their ships. Prior to the alignment, the vessel experienced constant vibration, leading to discomfort for the crew and higher fuel consumption. After the alignment was completed, the vibrations were significantly reduced, and fuel consumption decreased by 3%, leading to substantial savings over time.

Key Statistics on Propeller Shaft Alignment

- 3% reduction in fuel consumption due to proper propeller shaft alignment.

- 30% increase in the lifespan of the shaft and bearings with proper alignment.

- 4% decrease in operational costs from fewer maintenance requirements.

- 50% reduction in vibration-related complaints after alignment.

Frequently Asked Questions

1. How often should a propeller shaft be aligned?

The propeller shaft should be inspected and aligned regularly, typically every 1-2 years, or whenever there are significant operational changes, such as engine repairs or propeller replacements.

2. Can a misaligned propeller shaft be repaired, or does it need replacement?

In most cases, a misaligned propeller shaft can be realigned, provided it is not severely damaged. However, if the shaft shows signs of excessive wear or damage, replacement may be necessary.